How Hypochlorite Generators Work

Introduction

I still remember walking into a water treatment facility for the first time. The steady hum of machines mixed with the scent of fresh water.

In the corner stood a sodium hypochlorite generator system. At first glance, it looked like just another piece of equipment. But then I realized it was quietly producing sodium hypochlorite solution—the lifeline for safe drinking water.

Seeing salt and electricity transform into a disinfectant powerful enough to protect entire communities felt like standing in the middle of a science experiment. Yet this wasn’t theory. It was a real, practical solution ensuring that clean water reached every home. That moment stuck with me.

Today, let’s explore together how these systems work, why they matter, and how they’re changing the future of water treatment.

Why Ask “How Does a Hypochlorite Generator Work?”

Most of us take drinking water for granted. We open a tap, fill a glass, and trust it’s safe. But behind that simple act lies an entire process of water disinfection.

For decades, treatment plants relied on chlorine gas. It did the job, but it came with baggage.

Handling gas chlorine meant working with a hazardous material that demanded strict safety procedures. Transport trucks carried enormous risks. A leak or accident could be catastrophic.

That’s where site sodium hypochlorite generation comes in. With it, facilities produce sodium hypochlorite locally, avoiding the dangers of gas chlorine transport. For us in the industry, the shift feels like moving from carrying lit fireworks to using a safe lantern. Both provide light, but one clearly carries fewer risks.

The Core Science Behind It

When people hear “generator,” they imagine a loud machine burning fuel. But a sodium hypochlorite generator doesn’t work like that. Its fuel is much simpler—salt, water, and electricity.

Feed these ingredients into an electrolytic cell, and you get chemistry at work. The brine solution reacts under electrical current, producing sodium hypochlorite NaOCl.

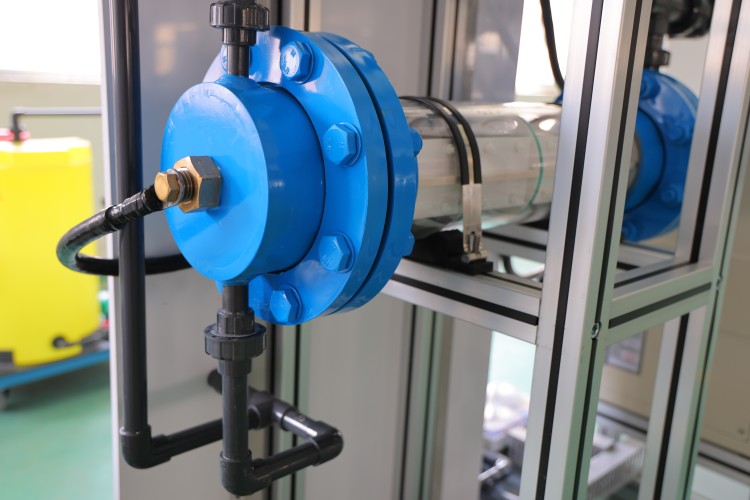

Breaking Down the Electrolytic Cell

Think of the electrolytic cell as the heart of the system. It works like a chemical factory in miniature. Inside:

Chloride ions release chlorine gas

Sodium ions react with hydroxide

Together they form sodium hypochlorite solution

What amazes me is how such a basic setup—salt and water split by electricity—creates a disinfectant strong enough for entire treatment facilities.

Salt and Electricity as the Key Ingredients

The beauty lies in the simplicity. Salt provides the sodium. Water dissolves the salt, forming brine. Electricity triggers the reaction.

High-purity salt keeps the process efficient. A steady electrical current ensures consistent output. The result is sodium hypochlorite solution produced on demand.

For operators, it feels like brewing coffee: add ingredients, push a button, and out comes what you need. Only this “coffee” safeguards drinking water.

Generating Sodium in Real Time

Unlike chlorine cylinders that must be delivered, hypochlorite generators keep running as long as they have salt and water. Systems can operate continuously or cycle depending on demand.

This means treatment facilities never run dry. Whether during peak summer usage or emergencies, the supply remains steady. And since the sodium hypochlorite solution is made fresh, it retains maximum effectiveness.

From Brine Solution to Safe Water

The journey begins with a brine solution but ends with safe water flowing into homes. Fresh sodium hypochlorite solution moves straight into the treatment process.

Role in Water Disinfection

The solution attacks bacteria, viruses, algae, and organic contaminants. Every drop adds to water quality. Every liter treated ensures safer drinking water for families, hospitals, and schools.

Benefits for Treatment Facilities

Why do operators prefer site sodium hypochlorite generation? Because it checks every box:

Safety: Eliminates chlorine gas storage and transport

Cost savings: Cuts long-term operating costs

Freshness: Produces sodium hypochlorite solution when needed

Flexibility: Fits both small plants and massive systems

Water quality: Improves stability and consistency

It’s like running a mini disinfectant factory that never stops.

Drinking Water and Beyond

The system doesn’t just protect municipal water. It finds use in:

Food production facilities

Cooling tower treatment

Hospital sanitation

Every application values the ability to generate sodium hypochlorite locally.

The Safety Advantage Over Hazardous Material

Chlorine gas works, but it brings danger. Transporting cylinders through cities feels like carrying a ticking time bomb. Operators know this risk all too well.

Onsite generation changes the game. By producing sodium hypochlorite solution directly at the facility, we eliminate hazardous transport.

No more trucks carrying gas chlorine. No more emergency drills for leaks. Just peace of mind.

Lowering Operating Costs

Yes, installing a generator requires investment. But over time, the benefits outweigh the costs. No need to constantly purchase gas chlorine.

No expensive storage infrastructure. And modern systems use less electricity, trimming power bills.

When we calculate total operating costs over years, the savings often surprise plant managers. What once looked like an expense becomes a smart investment.

Cutting Carbon Footprint

There’s another angle we often overlook—the environment. Each avoided chlorine delivery reduces carbon emissions. Site sodium hypochlorite generation lowers the carbon footprint of treatment facilities.

For communities aiming at sustainability, this shift matters. Clean water should not come at the cost of higher pollution. Generators balance both health and environment.

Common Misconceptions

We’ve heard the doubts:

“It’s too complicated.”

“It costs too much.”

“It’s unsafe.”

But let’s be honest. Operating a generator requires basic training. Long-term costs prove cheaper than chemical deliveries. And compared to chlorine gas, the system is far safer.

At its core, it’s just salt and water guided by electricity. Simpler than most people think.

The Future of Sodium Hypochlorite Generator Systems

Technology keeps moving forward. Modern generators already use advanced electrolytic cells that need less power. Control systems allow real-time monitoring, adjusting production automatically.

Compact units now fit in smaller spaces, making them suitable even for mid-sized towns. As demand for safer and greener water treatment grows, more facilities will adopt these systems.

The future isn’t about choosing between safety and cost. It’s about systems that deliver both.

Conclusion

So how does a Hypochlorite Generator work? The answer is elegant in its simplicity. Salt and water meet electricity in an electrolytic cell. The result is sodium hypochlorite solution—safe, fresh, and ready for water disinfection.

For us, it goes beyond chemistry. Every liter treated represents lives protected. Every system installed reduces risks from hazardous material. Every community served strengthens our belief in this technology.

Whenever I pour a glass of drinking water, I think of the silent generator running somewhere nearby. And I smile, knowing that behind the ordinary lies something extraordinary.