Revolutionize Maintenance with Auto Pickling

Taking care of a sodium hypochlorite generator used to be a chore—messy, manual, and time-consuming. But not anymore. At Shine, we’ve built a smarter solution.

Our automatic pickling car mounts directly on the Shine Sodium Hypochlorite Generator, allowing for in-place acid cleaning of the electrolyzer—fully automated. No more dismantling. No more downtime. Just efficiency, safety, and serious peace of mind.

🚗 What Is the Automatic Pickling Car?

It may sound like a car, but it’s actually a self-cleaning unit that connects directly to the generator’s electrolytic cell. It detects internal scaling and runs a full acid cleaning cycle without removing any parts.

🔍 Key Features:

· Direct connection to the electrolytic cell

· Timed acid injection with adjustable strength

· Circulation cleaning via built-in pump system

· Auto neutralization and rinse after cleaning

· Closed loop design prevents acid gas escape

💡 Why We Use It (And Why You Should Too)

Before we had the pickling car, we had to shut down operations, remove the cell, clean it by hand, and reinstall it. It took hours and multiple operators. Now? Just press “start.”

⚙️ Major Advantages:

1. No disassembly required—clean the cell in place

2. Smart control—cleaning cycles based on runtime or scaling detection

3. Safety first—full acid containment and leak-proof design

4. Saves labor and time—one person can operate it

5. Extends cell life—no harsh manual scrubbing

🛠 Our New Maintenance Routine

Since we integrated the auto pickling car, our maintenance workflow has completely changed. Here’s what it looks like now:

🔄 Monthly Cleaning Flow:

· The system checks for scaling

· If levels are high, it starts acid injection automatically

· The cleaning solution circulates through the electrolyzer

· After a set time, it flushes the system with clean water

· The generator resumes normal operation without manual reset

We used to spend 3–4 hours per cleaning. Now it takes 30 minutes, hands-free.

🧠 The Technology Behind the Magic

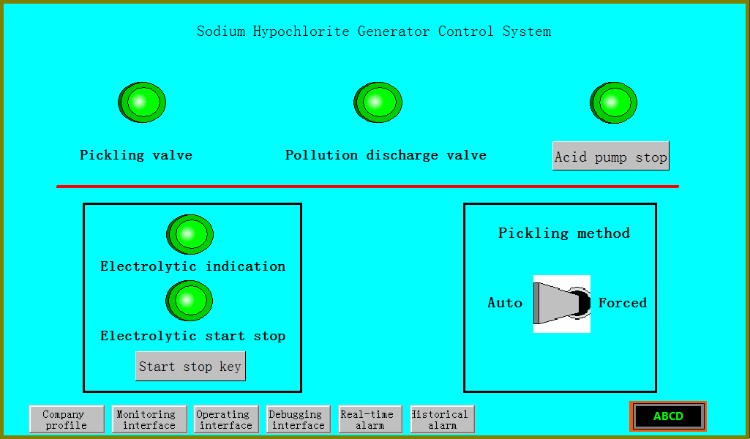

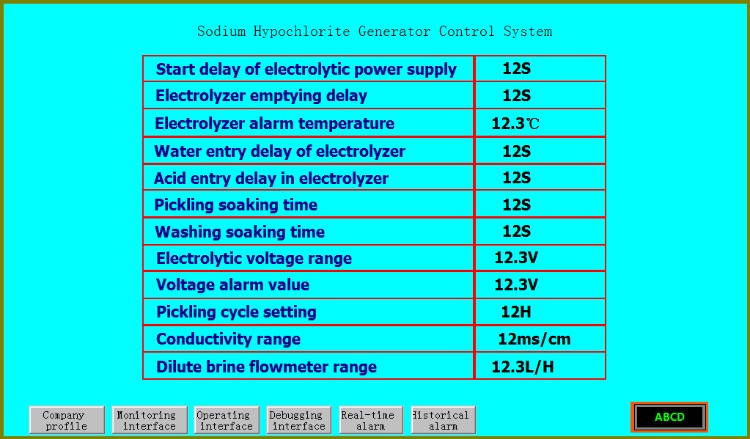

We didn’t just slap a pump on it. Our engineers designed an intelligent system that adapts to different cleaning needs. At the core is a PLC controller with an intuitive HMI panel.

🧩 System Highlights:

· Selectable modes: Light wash or deep clean

· Acid concentration control: Adjust according to scaling level

· Safety lockouts: Prevents accidental injection during operation

· Status display: Real-time pH, flow, and cycle progress

It’s smart, safe, and surprisingly simple to operate—even for first-timers.

⚠️ Watch Out for These

While the system handles most of the work, a few checks help keep it running smooth:

· Inspect acid hoses every 3 months

· Calibrate the acid dosing pump every 6 months

· Clean the acid tank annually to prevent sediment buildup

😎 Real Results from Our Field Team

Before automation, acid cleaning was dreaded. One technician told us,

"I used to bring gloves, goggles, and patience. Now I just tap a screen."

Another said, "This system cut our cleaning time by 80%. It even logs the cycle automatically."

These aren’t just tools—they’re upgrades to your whole workflow.

🧪 Built for Water Treatment, Built to Last

Whether you’re treating cooling water, wastewater, or municipal drinking supplies, our auto pickling system works quietly in the background—keeping your Shine Sodium Hypochlorite Generator performing like new.

And since no one likes surprise breakdowns, this system helps you plan ahead instead of reacting later.

🧾 Quick Recap Checklist

📌 Automatic pickling car = no cell removal

📌 Fully programmable cleaning cycles

📌 Safe closed-loop acid handling

📌 Quick setup + low maintenance

📌 Boosts performance + extends equipment life

We built it to make your job easier. And we use it ourselves—every day.