Where to Buy Chlorine for Water Treatment

When people ask where to buy chlorine for water treatment, we always pause before answering. Not because chlorine is rare. It is everywhere. But because how you buy it matters more than where. Over the years, we have seen good operators make bad choices simply by following old habits. We want to share what we have learned, honestly and clearly.

Water treatment keeps communities healthy. It also carries responsibility. Chlorine plays a vital role, yet it comes with safety, cost, and environmental impact. That balance shapes every decision we make in this industry.

Let’s walk through the real options, the hidden risks, and the smarter long-term path forward.

Traditional Places to Buy Chlorine

Most buyers start with traditional suppliers. This route feels familiar and easy at first. However, it comes with trade-offs that many overlook.

Chemical Distributors and Industrial Suppliers

Large chemical distributors sell chlorine gas, liquid bleach, and pool chemicals. These suppliers often serve municipal plants and industrial sites. They offer bulk pricing and steady supply contracts.

However, transporting chlorine is dangerous. Chlorine gas leaks cause serious injuries. Even small handling mistakes trigger shutdowns. Many operators tell us this risk keeps them up at night.

Costs also creep up quietly:

Special transport vehicles

Strict storage rules

Emergency response plans

Insurance premiums

Over the long term, these expenses grow faster than expected.

Pool Chemical Suppliers

Pool chemicals often contain chlorine compounds. Smaller facilities sometimes use these products for basic water treatment.

Yet these products target recreational water, not drinking systems. Purity varies. Dosing control suffers. Environmental impact often goes unmeasured.

This option works only in limited cases.

Why Transporting Chlorine Is Risky

We have visited facilities that still rely on chlorine gas cylinders. The tension is real the moment you step inside.

Chlorine gas poses serious hazards:

Toxic inhalation risks

Corrosive damage to equipment

Emergency evacuation requirements

One cracked valve can stop operations instantly. More importantly, it can harm people. That reality drives many operators to rethink their sourcing strategy.

Safety should never feel optional.

On-Site Generation Changes Everything

Here’s where the conversation shifts.

Instead of asking where to buy chlorine, many modern facilities ask something better:

Why not make it on-site?

Producing Chlorine Where You Use It

On-site systems produce disinfectant using simple raw materials. Salt, water, and electricity do the work. No trucks. No cylinders. No panic during delivery delays.

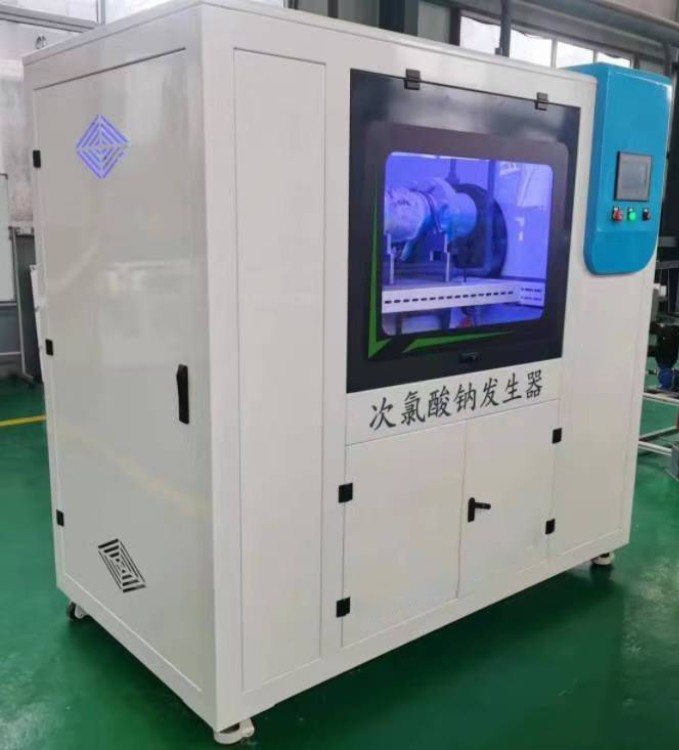

A Sodium Hypochlorite Generator produces Sodium Hypochlorite on-site and uses it immediately. That immediacy matters. Fresh solution works better and degrades less.

From our experience, this approach feels empowering. You control your process. You control your safety.

Environmental Benefits You Can Measure

Sustainability matters more each year. Regulators ask tougher questions. Communities expect better answers.

On-site production helps you meet those expectations.

Lower Environmental Impact Over Time

Traditional chlorine relies on fossil fuels across its life cycle. Mining, processing, packaging, and transport all add emissions.

On-site generation helps:

Significantly reduce greenhouse gas emissions

Cut carbon emissions from transport

Lower overall carbon footprint

These improvements stack up over the long term.

Supporting a Circular Economy

Using simple, recyclable inputs supports a circular economy. Salt remains abundant in natural resources. Systems reuse water efficiently. Waste stays minimal.

This approach promotes sustainable operations without sacrificing performance.

Raw Materials Matter More Than You Think

Every treatment method begins with raw materials. Some options hide complexity behind convenience.

On-site systems rely on:

Salt

Water

Electricity

That’s it.

These materials remain widely available. They reduce dependence on volatile supply chains. They also avoid hazardous byproducts.

We like solutions that stay boring and predictable. In water treatment, boring equals safe.

Energy Efficiency and Modern Design

Older chemical methods burn energy indirectly through transport and refrigeration. Newer systems flip that equation.

Modern generators focus on:

Energy-efficient operation

Smart dosing controls

Reduced waste output

Many facilities pair them with renewable materials and clean power sources. Solar integration already appears in several projects we’ve supported.

Eco-friendly design no longer feels optional. It feels inevitable.

Long-Term Cost Control

Price tags mislead. We have learned to think in years, not invoices.

Hidden Costs of Buying Chlorine

Traditional purchasing includes costs people forget:

Storage infrastructure

Safety training

Emergency systems

Regulatory compliance

Those expenses never disappear.

Predictable Costs with On-Site Production

On-site systems bring clarity:

Stable operating costs

Fewer surprise shutdowns

Reduced labor stress

Over time, facilities gain confidence in their budgets. That peace of mind matters.

Water Treatment Needs Consistency

Disinfection fails when dosing fluctuates. Fresh production improves consistency.

On-site solutions deliver:

Stable concentration

Immediate availability

Better process control

Whether treating drinking water or industrial systems, reliability defines success.

Environmental Responsibility Builds Trust

Communities care about how utilities operate. Transparency builds confidence.

Choosing sustainable materials and reducing waste sends a clear message. It shows leadership. It shows care.

We have seen public perception shift when operators explain their eco-friendly upgrades. That goodwill proves priceless.

Making the Smart Buying Decision

So, where to buy chlorine for water treatment?

You can still buy it from distributors. That path remains open. Yet more operators now choose to stop buying chlorine entirely.

Instead, they invest in control, safety, and sustainability.

From our side, we believe progress should feel practical, not trendy. On-site production simply solves too many problems to ignore.

Our Final Take

We feel optimistic about the future of water treatment. Technology now aligns with safety, cost control, and environmental care.

Choosing smarter systems helps:

Reduce risk

Lower carbon footprint

Support long-term stability

That combination feels right. It feels responsible. And honestly, it feels overdue.