- Home

- Sodium hypochlorite generator used for disinfection in animal husbandry

The importance of disinfection of aquaculture wastewater: Bacteria, viruses, and other microorganisms in the wastewater may cause respiratory diseases, digestive problems, and growth disorders in farmed animals. In addition, the odor substances in sewage can also have adverse effects on farmed animals. Therefore, effective disinfection treatment of wastewater from aquaculture farms is crucial.

Solution steps

The application of sodium hypochlorite generator in the disinfection of wastewater in aquaculture farms: Sodium hypochlorite generator can be widely used in the treatment of wastewater in aquaculture farms to disinfect wastewater and effectively remove bacteria, viruses, and odors. The application process is as follows:

Step 1: Wastewater pretreatment: The wastewater from aquaculture farms usually contains suspended solids, sediment, and organic matter. Before using the sodium hypochlorite generator, it is necessary to pretreat the wastewater, such as sedimentation, filtration, and removal of impurities, to reduce the impact on the sodium hypochlorite generator.

Step 2: Sodium hypochlorite generator operation: Connect the sodium hypochlorite generator to the sewage treatment system. Adjust the operating parameters of the sodium hypochlorite generator based on the nature of the wastewater and disinfection requirements, such as solution concentration, flow rate, and contact time. Usually, automatic adjustment and monitoring can be achieved through intelligent control systems.

Step 3: Disinfect the wastewater by passing it through a sodium hypochlorite generator, allowing the solution to come into full contact with the wastewater. Hypochloric acid in sodium hypochlorite solution has a strong oxidizing and bactericidal effect, quickly killing bacteria, viruses, and other microorganisms in wastewater.

Step 4: Mixing and stirring: During the process of contact between sodium hypochlorite solution and sewage, ensure uniform distribution of the solution and increase disinfection effect through mixing and stirring.

Step 5: After disinfection treatment is completed, let the sewage stay in the retention or sedimentation tank for a period of time to allow residual bacteria, viruses, and suspended solids to settle.

Step 6: Purification and discharge: The wastewater after disinfection and sedimentation has greatly reduced the content of pathogens, and can be further purified through processes such as filtration and activated carbon adsorption. Ultimately, the purified wastewater can meet environmental discharge standards or be used for agricultural irrigation and other purposes.

Equipment display

Product parameters

Effective chlorine production: 50-400000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+86 15806625431

Email: info@sdshinemachinery.com

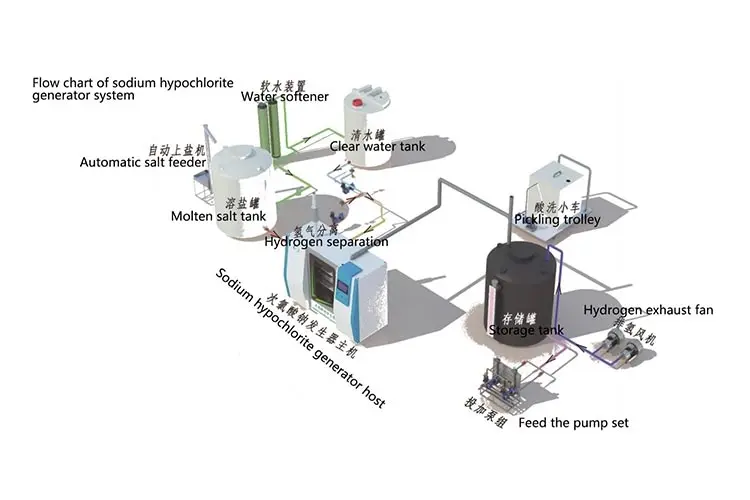

Process Flow Diagram

Disinfection scenario

Qualification certificate

Submitted successfully

We will contact you as soon as possible