- HOME

- Products

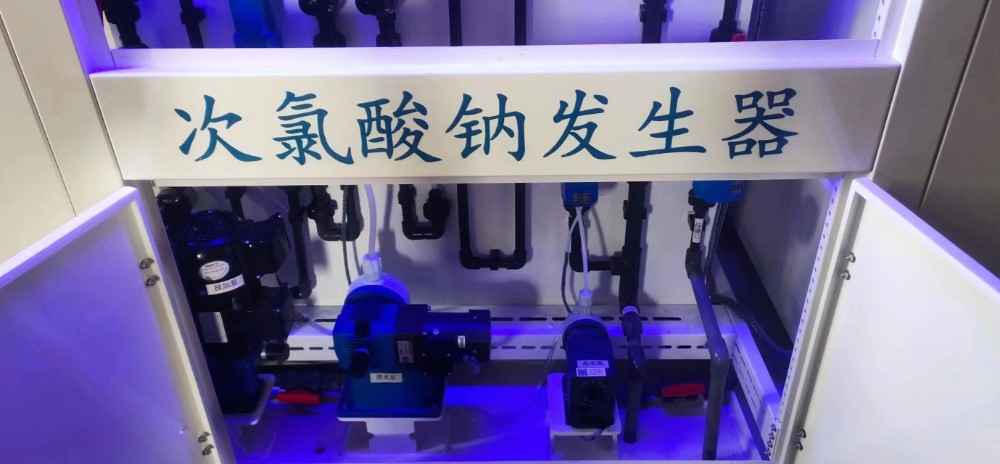

- Sodium Hypochlorite Generator

- On-Site Hypochlorite Generation System

Effective chlorine production: 50-60,000g/H

Effective chlorine concentration: 0.8% (8000PPM)

Installed power: 0.3-90 kW

Host size: customized

Delivery cycle: 25 days

WhatsApp: +8619953182842

Email: henry@hoclshine.com

On-site hypochlorite generation system creates sodium hypochlorite (NaClO) straight at the area where it will certainly be used. This removes the need for moving and keeping pre-made solutions. This technique, known as on-site sodium hypochlorite generation, offers numerous advantages over typical techniques.

First, it enhances safety and security by removing the threats connected with carrying and saving dangerous chemicals, therefore reducing the possibility for mishaps and spills.

Second, it gives expense savings, as generating hypochlorite on-site is typically extra cost-effective than purchasing mass sodium hypochlorite. Furthermore, on-site generation reduces the ecological influence by reducing the demand for chemical production and transport.

Lastly, it provides specific control over the concentration and dosage of hypochlorite, guaranteeing ideal use.

Specifications | Parameter |

50–60,000 g/h | |

8 g/L | |

Installed Power: | 0.3–90 kW |

Salt Consumption: | 3.2-3.5 Kg/Kg |

Host Size: | Customizable |

Delivery Time: | 25 days |

Sodium hypochlorite dissolves easily in water, achieving consistent chlorine residuals in factory water. Unlike chlorine gas, no excess needs to be added for effective results, making it a more efficient option.

The slower hydrolysis of sodium hypochlorite, combined with its alkaline nature, ensures a longer-lasting disinfectant effect in water systems compared to chlorine gas.

Sodium hypochlorite reduces the risk of leaks or hazardous by-products like dichloroacetic acid (DCAA) and trihalomethanes (THMs). Studies have shown it produces fewer harmful compounds than chlorine gas during disinfection.

Unlike chlorine, which can form corrosive hydrochloric acid, sodium hypochlorite is gentler on metal pipes and infrastructure, leading to less damage over time.

Sodium hypochlorite is easier to transport, and its raw materials are readily available, making it a practical option for large-scale industrial use.

The On-Site Hypochlorite Generation System consists of six integrated modules to ensure a seamless operation:

Each component works together to produce and deliver a reliable and consistent disinfection solution with minimal maintenance and maximum efficiency.

For inquiries or orders, please contact us:

WhatsApp: +86 19953182842

Email: henry@hoclshine.com

Submitted successfully

We will contact you as soon as possible