What Are Water Treatment Plants

Water touches every part of our lives. We drink it, cook with it, and trust it during every shower. So we often ask, what are water treatment plant systems, and why do they matter so much? We work in water treatment every day, and we still feel amazed by how these facilities protect human consumption.

A treatment plant is not just a big tank with pipes. It is a smart system that uses science, engineering, and strict monitoring. These treatment facilities clean raw water from rivers, lakes, or wells. They remove dirt, germs, and harmful chemicals so communities can enjoy safe drinking water.

What Are Water Treatment Plants?

Water treatment plants are places where experts treat water to make it safe. They use physical, chemical, and biological treatment methods. Each step improves water quality and protects public health.

We like to think of a treatment plant as a “water hospital.” Raw water comes in sick. Clean water leaves strong and is ready for human consumption.

These plants handle:

Surface water from rivers

Groundwater from wells

Stored water from reservoirs

Engineers design treatment facilities based on local water sources. Different water needs different treatment chemicals and processes involved.

Why Water Treatment Matters for Us All

Clean drinking water keeps cities alive. Without proper water disinfection, bacteria spread fast. Viruses travel through contaminated supplies and cause outbreaks.

We feel proud when we help improve water systems. Good treatment methods reduce disease and support long life. Strong water treatment also protects schools, hospitals, and homes.

Water quality also affects:

Taste and smell

Pipe corrosion

Appliance life

Industrial performance

So yes, water treatment plants quietly run the world.

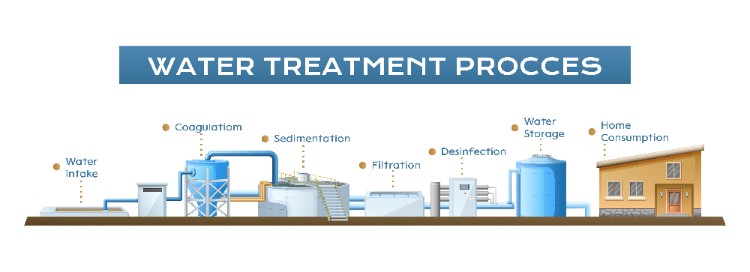

Main Stages Inside a Treatment Plant

Every treatment plant follows a clear path. Operators move water step by step. Each stage targets different contaminants.

Coagulation and Flocculation

First, operators add treatment chemicals that cause particles to clump. These tiny bits include dirt and organic matter. The process forms larger “flocs” that we can remove.

We often use metal salts at controlled parts per million ppm levels. Proper dosing matters. Too little fails, too much wastes money.

Sedimentation

Next, water rests in large tanks. Gravity pulls heavy flocs to the bottom. Operators remove the settled sludge from the basin.

This step reduces cloudiness. It also prepares water for the next filtration stage.

Filtration

Filters act like a physical barrier. Layers of sand and gravel catch small particles. Some plants add activated carbon to remove odors and chemicals.

Activated carbon also improves taste. It absorbs organic compounds and some pesticides.

Advanced Treatment Methods That Improve Water

Modern treatment facilities go beyond the basics. We now use smarter tools and tighter control.

Membrane Filtration

Membranes act like ultra-fine screens. They block bacteria and many viruses. This method works well for high-risk water sources.

Operators monitor pressure and flow. A sudden change signals fouling or damage.

Activated Carbon Adsorption

We already mentioned activated carbon, but it deserves more love. It grabs dissolved contaminants that normal filters miss. It helps improve water for both safety and comfort.

Many plants use granular activated carbon beds. Others inject powdered carbon during treatment.

Water Disinfection: The Critical Final Shield

Water can look clean but still hide microbes. That is why water disinfection stands as the final barrier. This step protects drinking water all the way to the tap.

Operators often use chlorine-based solutions. They measure concentration in parts per million ppm. Even small levels kill bacteria and viruses.

One common strength is 8000 PPM (0.8%) in stock solutions. Plants dilute this to safe residual levels before distribution. Proper control keeps water safe without a strong taste.

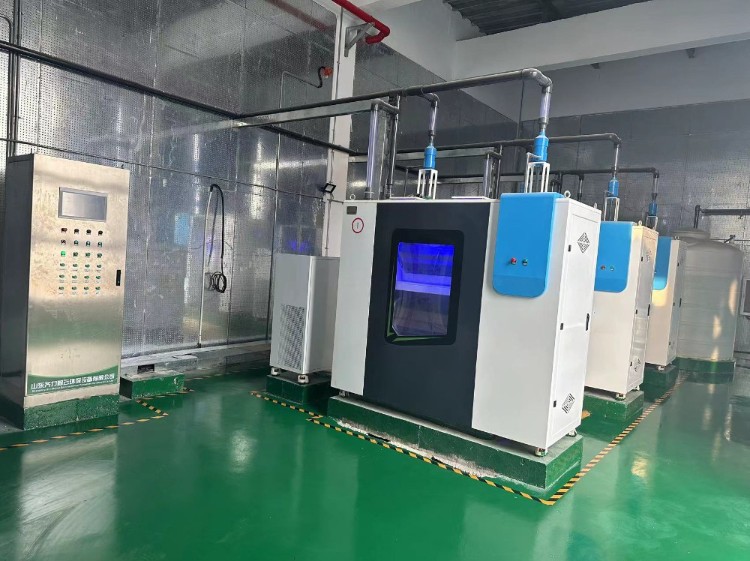

We support systems that generate disinfectant on-site. These solutions reduce transport risks and improve supply reliability. The On-Site Hypochlorite Generation System produces sodium hypochlorite from salt and water. Plants then use it immediately for water disinfection.

How Treatment Chemicals Work Together

Treatment chemicals do not act alone. They form a team that targets many threats.

Common chemicals include:

Coagulants to remove particles

Lime to adjust pH

Chlorine compounds for disinfection

Carbon for adsorption

Operators test water constantly. They adjust doses based on raw water changes. Rain, storms, and seasons all affect water quality.

We admire the skill of plant operators. They react fast and keep systems stable.

Monitoring Water Quality in Real Time

A treatment plant never sleeps. Sensors track turbidity, pH, and disinfectant levels. Labs test samples for bacteria and chemicals.

Monitoring water quality ensures safety for human consumption. Operators log data and follow strict standards. They act before small issues grow big.

Key checks include:

Residual disinfectant level

Turbidity after filtration

Microbial counts

Chemical balance

These checks help treatment facilities maintain trust.

From Plant to Tap: The Distribution Journey

Treatment does not end at the plant gate. Pipes carry drinking water across cities. Operators must maintain disinfectant residual during this journey.

If levels drop, microbes may grow. Good system design prevents dead zones and stagnation. Regular flushing also keeps water fresh.

We see the whole system as one chain. A weak link anywhere can affect water quality.

Challenges Water Treatment Plants Face

Running a treatment plant is not always easy. Source water changes fast. Climate events bring more pollutants.

Common challenges include:

Algae blooms in reservoirs

Industrial pollution

Aging pipes

Rising demand

Still, modern treatment methods and smart control help plants adapt. We stay optimistic because technology keeps improving.

A Human View on Water Treatment

We do not just see pipes and tanks. We see families drinking safe water. We see children filling bottles at school.

That emotional side drives our work. When treatment facilities run well, communities thrive. Clean water supports health, growth, and happiness.

Sometimes we joke that water treatment is “invisible hero work.” Nobody cheers when taps run. But everyone notices when they do not.

The Future of Water Treatment

Future plants will use more automation and data. AI tools will predict water quality changes. Energy-efficient systems will lower costs.

On-site generation of disinfectants will also grow. Plants gain independence and improve safety. Smart design helps improve water in remote and urban areas alike.

We believe water treatment plants will become even more advanced. But the mission stays simple: treat water, protect life.

Conclusion: Quiet Guardians of Drinking Water

So, what are water treatment plant systems in simple words? They are guardians of public health. They use science, treatment chemicals, and smart monitoring.

They remove contaminants, perform water disinfection, and deliver safe drinking water. Every step improves water quality and protects human consumption.

We feel honored to work in this field. Clean water may look ordinary, but it carries extraordinary effort behind it.